Big news in the battery-recycling world. Scaling its operations up, on Wednesday, Aqua Metals announced it plans to build an entire campus in the Reno, Nevada area dedicated to processing more than 20 million pounds of lithium-ion battery material each year.

SEE ALSO: Breakthrough recycling process for lithium-ion batteries is clean, quick and economically viable

To achieve this monumental goal, the company is acquiring a five-acre site with an existing a building. Aqua Metals plans to transform this structure into a commercial-scale recycling facility, one that can handle some 3,000 metric tons of battery “black mass” each year, 30 times what their existing pilot plant is capable of processing. The redevelopment of that existing building is expected to be completed this year, with commercial operations kicking off early in 2024. Once up and running, this new facility could reclaim enough materials to manufacture around 100,000 average-sized electric vehicle battery packs per year, a huge amount.

“Our campus vision is a testament to Aqua Metals’ commitment to the future of sustainable lithium battery recycling essential to meeting U.S. electrification and battery manufacturing ambitions in the coming decade,” said Steve Cotton, president and CEO of Aqua Metals in a release shared by the company.

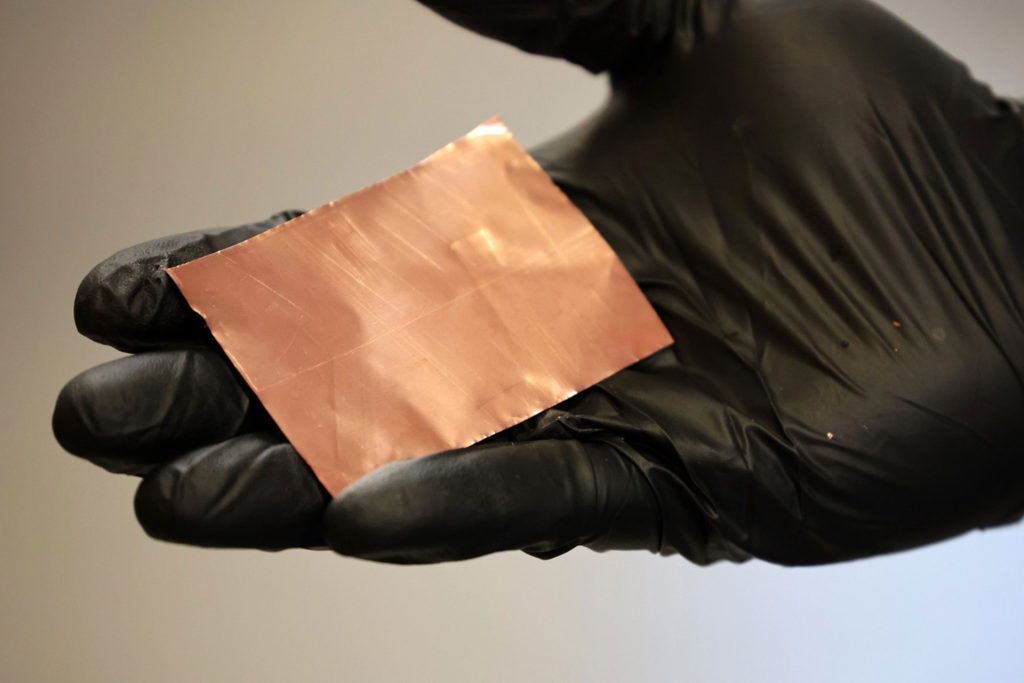

Aqua Metals developed an environmentally responsible – and economically viable – way of recycling lithium-ion batteries once they reach the end of their useful lives. The company’s Li AquaRefining process can sustainably recover materials including cobalt, copper, nickel and even lithium hydroxide. The ability to reclaim these core substances is critical if electric vehicles are going to take over the world’s roads, because we probably won’t be able to mine enough of this stuff to meet demand.

Compared to smelting, the way lithium-ion batteries have historically been recycled, the Li AquaRefining process uses a patent-pending electroplating process that reclaims high-purity metals and emits no harmful fumes like a furnace would. One-time-use chemicals are also avoided and, of course, if renewable energy is factored in, like Aqua Metals uses at its nearby pilot plant, this recycling process is even more environmentally friendly. Talk about having your cake and eating it, too. The Li AquaRefining process almost sounds too good to be true, but the results speak for themselves.

Once Phase One is up and running, Aqua Metals plans to initiate Phase Two, that is, building an additional facility on the same five-acre property. This second recycling plant would be able to process an additional 6,000 tons of black mass annually, increasing their capacity immensely. Adding more research and development space would also be included in Phase Two.

BIG NEWS: Are there enough critical materials to support global EV adoption? Maybe not

“Our plans also represent a meaningful investment in clean-energy jobs in the Nevada battery industry, as a leader in the effort to create a secure and sustainable domestic supply chain for the metals needed to power electric vehicles and build battery energy storage systems,” said Cotton.

If Aqua Metals is successful, Nevada could become the heart of the lithium-ion battery supply chain in the US. Companies mining new materials, manufacturing cells and even recycling old battery packs will all be present and active in The Silver State, though perhaps Nevada’s official nickname should be changed to The Lithium State.