What if your electric vehicle’s lithium-ion battery were better in every way, if it offered significantly more range, charged much faster and lasted years longer before losing capacity? This sounds too good to be true, but The Coretec Group, an Ann Arbor, Michigan-based company is developing technology that checks all those boxes and more.

It’s still in the lab right now, but the firm’s Endurion battery program could revolutionize future EVs. To achieve this, researchers have developed something of a secret sauce comprised of two primary ingredients: anodes made with silicon nanoparticles and a special elastomer coating. Together, these advancements help unlock myriad – and significant – benefits.

In an interview with EV Pulse, Dr. Ramez Elgammal, chief technology officer at The Cortec Group, said that “even with silicon loadings up to 30, 40% or so, you can easily double your range,” a staggering improvement, because it “has a theoretical capacity that’s 10 times that of graphite,” the material used in anodes today. And if that’s not impressive enough, Endurion batteries are expected to absorb energy far quicker across the board, able to hit an 80% state of charge in as little as 6 minutes plus they should be less susceptible to frigid conditions. “The active material in Silicon anodes is better at low temperature than [what] is in graphite,” Elgammal added, meaning EVs would perform much better in frosty winter weather.

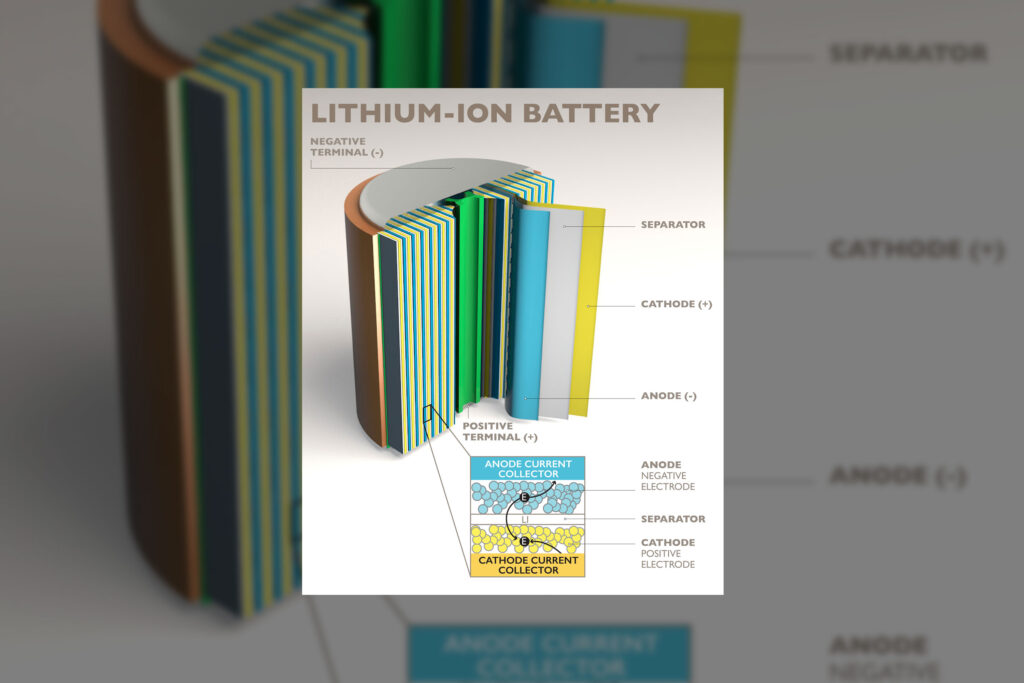

These are great reasons to go with silicon-rich anodes, but the problem is this material is cantankerous when used in batteries because “it expands around 300% or so during cycling (charging and discharging),” which Elgammal noted can cause the solid electrolyte interface (SEI) to become dynamic, breaking apart and reforming. “And as that happens,” he noted, “it can trap lithium in it. And so, that lithium then becomes irreversibly trapped,” increasing both the SEI’s ionic and electrical resistance, reducing battery capacity.

Using lab-grown silicon nanoparticles instead of what would normally be sourced from Mother Nature can help reduce expansion and contraction while also being less prone to breaking down over time and fouling the electrolyte. Additionally, The Coretec Group has engineered an elastomer material for battery anodes, and it does some amazing things.

“[The Endurion coating] is a special polymer that we’ve developed … the properties of it are that it has very high lithium-ion conductivity,” said Elgammal. Beyond that, this layer “is mechanically robust, so that as the particle swells and contracts during charging and discharging … it’s adhered well to the surface of the particle and has flexibility, so the coating doesn’t fracture along with the particle.” He added that this allows the anode to hold its shape “so that it’s not breaking, reforming and breaking, reforming and trapping lithium,” thus improving cycle life.

Think of Endurion as a permeable plastic coating around those nanoparticles. This layer easily allows ions to pass through – you know, so the battery can actually provide power – but it holds the silicon together, permitting it to expand and contract without crumbling. It’s a clever solution that allows far more silicon to be used in anodes, and more silicon makes for a faster charging battery with greater capacity.

Companies, including Aqua Metals, are working on developing clean, safe and efficient ways of recycling lithium-ion batteries when they reach the end of their useful lives. And the good news is, Endurion-type cells should be just as recyclable as any other lithium-ion battery. According to Elgammal, though, much more work has been done developing ways of recycling cathodes, because they contain highly valuable metals like cobalt, whereas the anodes do not. “There should be a way to recycle the silicon that’s in there,” he said, “but we haven’t thought too much about that,” at least not yet.

Will your next EV feature a silicon-rich battery pack that can fully charge in less than 10 minutes and have 1,000 miles of range? Probably not. “We don’t know yet when it would be commercialized,” said Elgammal, though when Endurion technology does hit the market at scale, he noted it should have cost parity with graphite anodes while providing numerous other benefits.

As for manufacturing and selling finished batteries, that’s not something The Coretec Group is focusing on. “We do have plans for later this year to start providing materials to third parties for evaluation,” said Elgammal, but “the overall business model right now is either to look at licensing opportunities for the technology or think about forming partnerships.”

A battery breakthrough like Endurion is ideal for electric vehicles, where the ability to quickly absorb large amounts of energy is important, though it’s not hard to see this technology being used in consumer electronics or even future electric vertical takeoff and landing aircraft. Hopefully The Coretec Group can commercialize its Endurion battery technology sooner than later.