For drivers that are considering an electric vehicle, range is often the No. 1 concern, especially for those living in regions where the weather gets cold. Of course, countless companies around the world are hard at work addressing this issue, coming up with innovative ways of increasing how far an EV can go between charges. At CES 2023, we found five upcoming technologies that promise to increase electric vehicle range.

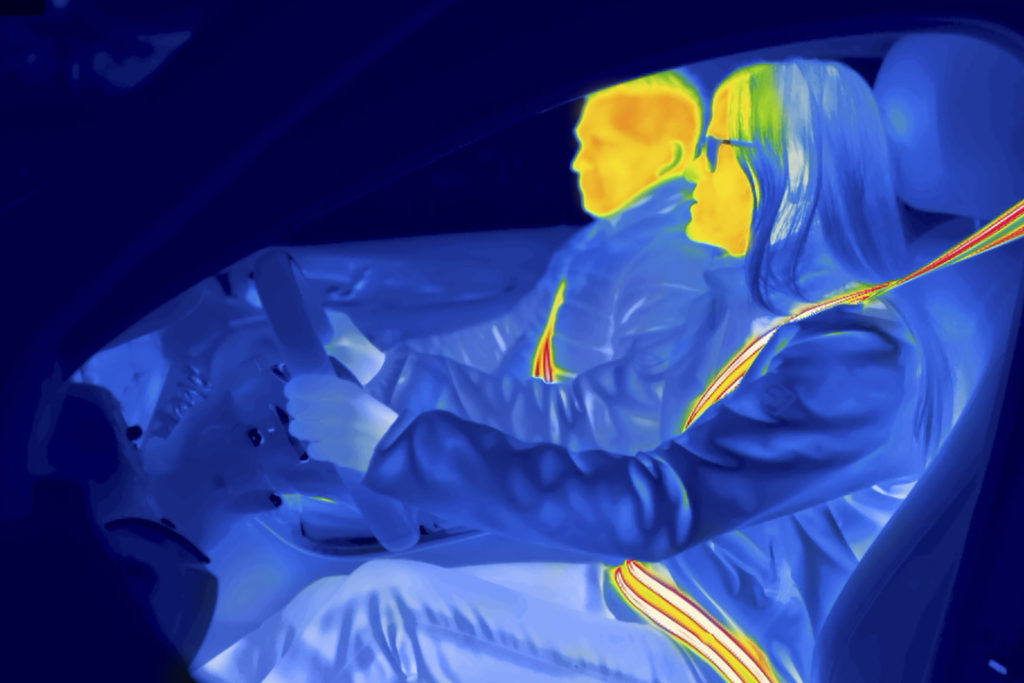

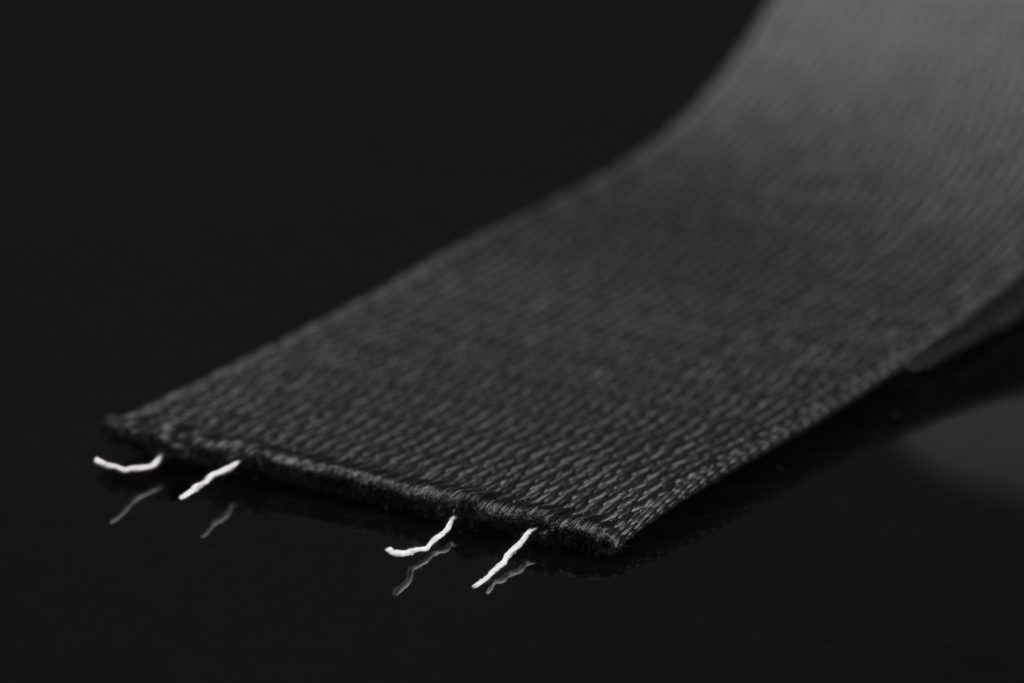

Heated seat belts cut HVAC usage

Giant German supplier company ZF used CES to unveil its new Heat Belt. Yes, as the name implies, this is essentially a heated seat belt. And yes, that sounds a bit frivolous, but the company promises this feature can make a big difference. When used in conjunction with a heated steering wheel and heated seats, this body-warming belt is said to increase vehicle range by up to 15%. That is a bold claim and seems a bit generous on the surface, but this innovative feature could really deliver the goods since, when activated, a vehicle’s HVAC system would not have to be used nearly as much in cold weather. Think of this as a nice, warm hug from the vehicle you’re driving.

SEE ALSO: Innovative new tech from Symbio boosts hydrogen fuel cell life by 20%

According to ZF representatives, engineers figured out how to weave a conductive webbing through a conventional seat belt. The Heat Belt should feel no thicker or any different from a conventional belt, though it draws up to 70 Watts of power and heats up to around 104 degrees F (40 C). The Heat Belt is not available in any vehicles yet, but automakers are interested in this range-extending technology.

Brilliant tech can completely defrost a windshield in just one minute

One of the most absolutely ingenious range-increasing items we saw at CES this year was developed by a company called Betterfrost Technologies. They’ve figured out how to completely clear a vehicle’s icy windshield at -4 F (-20 C) in just 1 minute, so no scraping, chiseling or waiting required. This is 20 times faster and the technology uses 20 times less energy than conventional defrosters, which can equate to 20 miles of extra range, or more.

How does this work? Well, Betterfrost Technologies’ system pulses high voltage electricity through the windshield’s existing thermal conductive coating, the component sandwiched between glass layers that reduces thermal gain in sunny weather. When active, this melts a super-thin layer of ice, basically breaks its bond to the glass, so the ice sloughs right off.

Aside from clearing windshields, this technology can also be used to keep freezer evaporators free of frost, which can save cold-storage facilities loads of money and time; the tech can even keep ice off aircraft wings, causing a whopping 3 inches of ice to break away in a mere 2 minutes.

Batteries with 70% more energy density are under development

One of the easiest ways to increase the range of an electric vehicle is by improving the energy density of its battery pack. And that’s exactly what Dutch company LeydenJar aims to do.

CHECK IT OUT: New tech from Magna can change a vehicle’s shape before your very eyes

This firm has figured out how to make lithium-ion batteries a whopping 70% more energy dense than current designs, which is a massive increase. To do this, LeydenJar has developed special anodes that are built around super-thin copper sheets. These anodes are then coated in silicon instead of graphite. Silicone is estimated to be 85% better for the environment than graphite since it’s basically sand, a material that is also super abundant.

These silicon-coated anodes are 10 times thinner than their graphite counterparts, about the thickness of a red blood cell compared to the thickness of a human hair. That doesn’t sound like much, but it’s a huge difference, and it’s what allows them to cram far more anodes into a given space, which is where the 70% energy density figure comes from.

Aside from that, this new battery configuration should be a fast-charging champ. In automotive applications, LeydenJar representatives said their design should be able to hit a 60% state of charge in just 6 minutes, regardless of the battery’s overall capacity.

Naturally, OEMs are extremely interested in this technology. LeydenJar is already working with BMW, but undoubtedly they’ll be receiving calls from other automakers as well. The company estimates their battery technology will be in cars by the end of the decade. Once scaled up, the cost of this new tech should be the same — or potentially even lower — than today’s lithium-ion batteries.

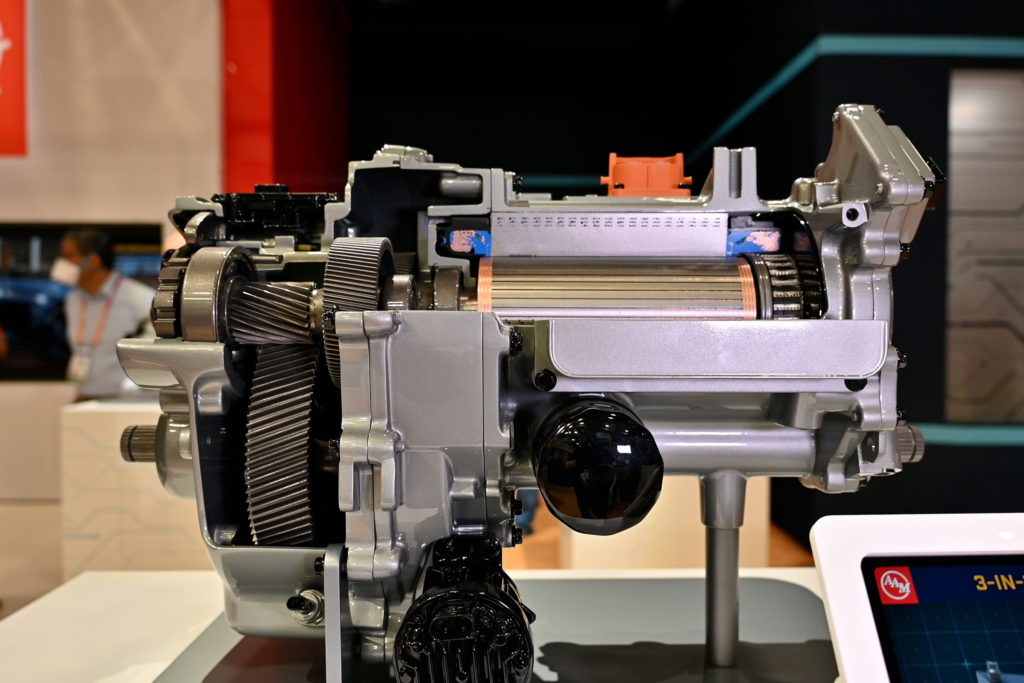

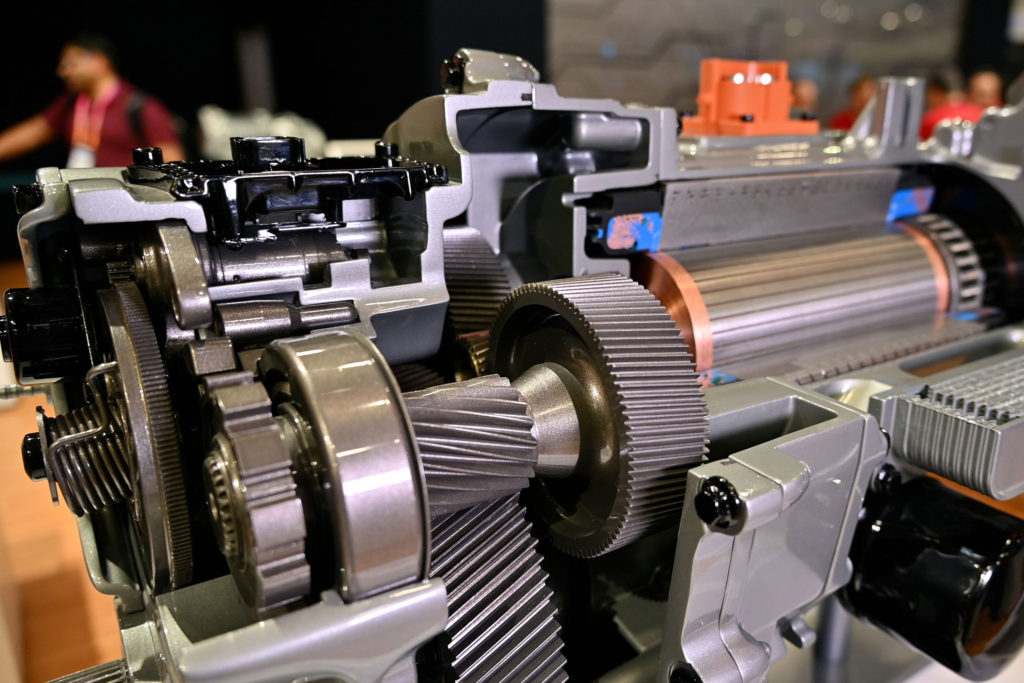

Clever 3-in-1 drivetrain unit saves space and is significantly more efficient

AAM is best known for building traditional axles and related driveline parts, though the supplier company also makes plenty of components for electric vehicles. Promising a more efficient future, the firm’s 3-in-1 electric drive unit, or EDU for short, was on display at CES.

This clever bit of engineering combines the motor, inverter and reduction gearset into one housing. This packaging makes the overall unit much smaller and reduces weight, too. AAM claims this design can improve efficiency by up to 10%.

Major drivers of this impressive performance include an electric motor with a rotor that’s 40% less massive, which, in part, helps it spin faster, up to 24,000 rpm. Additionally, a twin-layshaft design on the output reduces bearing loads and helps enable that significantly elevated redline.

WOW IS THE WORD: Ram Revolution BEV Concept teases us the electric Ram future

Pressurized oil cooling is another major driver of improved efficiency. All internal components are oil cooled, and engineers even included a spin-on filter to help keep debris from circulating through the EDU. This improves not only performance and efficiency, but longevity as well.

AAM representatives expect this 3-in-1 unit to hit the road in production applications in 2024. It’s sized to work in a wide range of vehicles, everything from a Jaguar iPace to a BMW 3 Series or 5 Series to a mid-size pickup truck. Further broadening its appeal, this electric drive unit will be offered in a range of outputs, including 100- and 200-kilowatt varieties (134 and 268 horsepower, respectively).

Space-inspired airless tires slash rolling resistance to improve range

Drivers don’t often think wheels and tires play much of a role in vehicle range, but they are a huge factor. The BMW i4 M50, for instance, offers an EPA-estimated 271 miles of range when fitted with 19-inch wheels, a respectable figure. If you opt for 20s from the factory, however, that figure drops to just 227, a decrease of 44 miles just from the wheels and tires!

At CES we ran across The Smart Tire Company, which is based in Ohio, and they’re developing airless tires that use coils of special shape-memory alloy metal instead of pneumatic pressure. Inspired by the mesh-like tires used on the lunar rover, this company believes they can improve the efficiency of roadgoing vehicles by building tires that have less rolling resistance. Of course, this applies to EVs as it should to other roadgoing vehicles.

The metal in question is a nickel-titanium blend that achieves a 6% strain before yielding, basically, that means a wire made of this material can be stretched up to 6% and still spring back to its original form, which a company representative said is absolutely unheard of. To demonstrate this, they had samples of this wire attached to a board and a handle. While standing on the board, you pull the handle and it literally feels like you’re tugging on a strong spring, yet it’s just the wire elongating and contracting again.

The Smart Tire Company is testing designs on bicycles and other so-called micro-mobility applications. Sooner than later, they hope to offer tires for automotive, commercial and even aeronautical applications.

Too much to cover at CES

And that’s just a taste of what was on display at this year’s CES. If we had more time in Las Vegas, we would have uncovered even more range-extending technologies and other cool features for electric vehicles. Of course, if you can’t get enough of this, visit EVPulse.com early and often and make sure you’re subscribed to our YouTube channel.