Battery technology has come a long way, particularly over the last decade, but energy density and cost are still huge issues standing in the way of the more-widespread adoption of electric vehicles. Working to address this issue, Our Next Energy, a battery technology company based in Novi, Michigan and founded in 2020, announced on Tuesday that its Aries II lithium iron phosphate (LFP) technology has advanced to within 6% of nickel cobalt manganese (NCM) batteries in range and mass, huge improvements with potentially wide-ranging implications.

Traditionally, the NCM chemistry offers significantly more energy density than LFP, however, the latter option is not without its own benefits. Lower cost, greater durability and enhanced safety are but a few of the significant advantages of the LFP battery chemistry.

In a release shared by the company, CEO and founder Mujeeb Ijaz said, “The key shortfall has been range and energy density. By engineering a battery pack with similar energy density to NCM, ONE (Our Next Energy) has made LFP a sustainable alternative.”

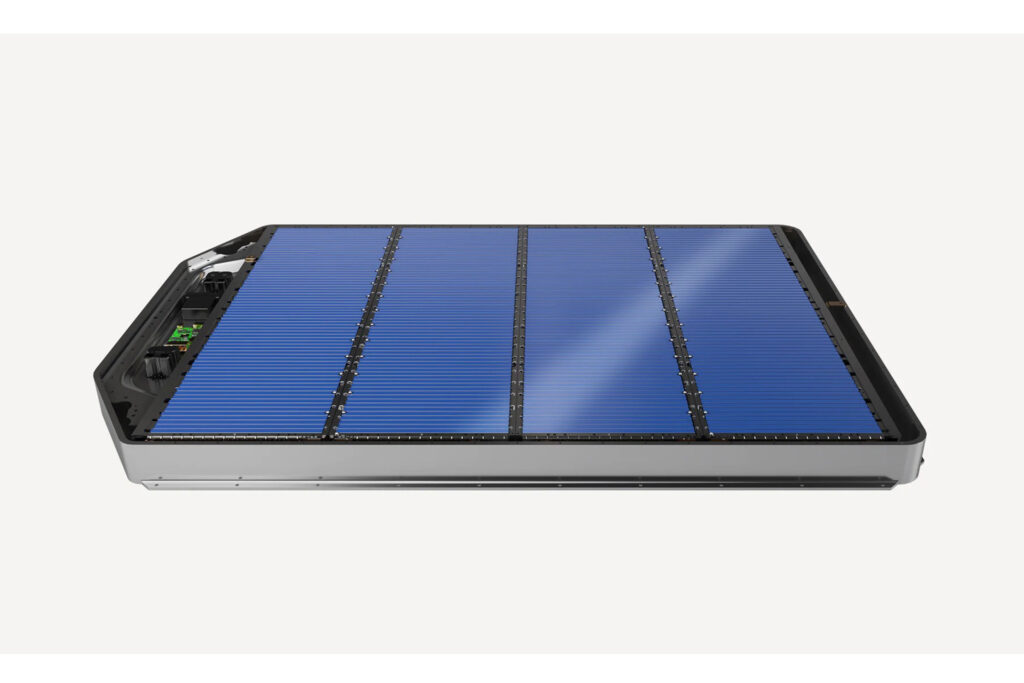

Our Next Energy’s latest offering has addressed the major shortcoming of this technology and increased energy density by 20% to 30% compared to other LFP designs. This means the company’s new Aries II battery can, in a typical all-electric passenger car, provide more than 350 miles of range, an excellent performance for any EV today.

The Aries II design is expected to offer 34% more energy density compared to other LFP batteries. With zero cobalt and nickel, this pack is also estimated to cost a whopping 25% less than similar NCM batteries, a huge savings.

Aside from incorporating widely available and more economical materials — the earth’s crust is estimated to be around 5% iron, compared to less than 0.01% cobalt and nickel — LFP batteries are also significantly safer than their NCM brethren. If a cell shorts out or gets crushed, it’s far less likely to self-oxidize. Thermal runaway, fancy term for fire, is a much bigger risk with NCM batteries.

Technological advances like this are certain to help spur the adoption of electric vehicles, lowering their cost and increasing range. Hopefully the charging infrastructure can keep up.

According to Our Next Energy, production of the new Aries II battery is expected to begin late next year. The company has a manufacturing facility in Van Buren Township, Michigan.